Matsushima Kumihimo / Iga Silk Braid

Story to show Japanese craftsmanship through the things, the place and the people related to Cohana’s products. Our second story is Iga Silk Braid of “Shozaburo Thread Snips with Iga Silk Braid” from Matsushima Kumihimo.

Kumihimo, a traditional craft, was featured in a movie released in 2016, and has suddenly come into the spotlight. Kumihimo has a long history, dating back to the Nara period (710-794). The technique used for stringing armor and Buddhist altars eventually blossomed in the culture of kimono, and many different ways of braiding techniques were born.

The luster of the beautiful silk thread has always captured the hearts of people, both now and in the past.

The Braids fot Cohana’s “Shozaburo Thread Snips with Iga Silk Braid” are carefully braided and wrapped one by one by the hands of craftsmen at Matsushima Braided Cord Store, which has been in this area for four generations. We headed to Iga to have a special opportunity to talk with them.

▲Iga is famous for the Iga Ninja. There are ninja motifs everywhere in the town.

▲Before the interview, we dropped by the recently reopened “Museum Iga Kumihimo, Home of the Braided Craftsman”. The small items made with the technique of kumihimo were gorgeous to the eye, and it was fun just to look at them.

▲We arrived at this Japanese traditional county house “Kumihimo studio Araki,” is the studio and the store of Matsushima Kumihimo. The house has an exquisite atmosphere.

The current craftsmen at Matsushima Kumihimo are Mr. Shunsaku, the third generation traditional craftsman, and his wife, Hiromi, who is good at knotting, and his sons Kenta and Yasutaka who are the fourth generation. We spoke with them as soon as we got their studio/store.

ー Can you tell us about the history of your store?

In 1932, Yoshio Matsushima, the first generation of the company, started business as “Matsushima Kumihimo Agency” in Iga City.

In terms of the history of kumihimo, the 1900s must sound pretty recent, right?

ーYou once told us that the history of kumihimo dates back to before the Nara period (710-794).

Originally used for Buddhist and military tools, the cord blossomed on the culture of kimono, gaining popularity as “obijime” and “haori-himo” and demand for braids grew. This was after the Edo and Meiji periods. The culture of kimono existed before then, but it must have been a luxury item because it used expensive “silk threads” and “gold threads”.

The number of craftsmen specializing Kumihimo braids called “himo-ya” making their living only from the braids increased as it spread to the general public.

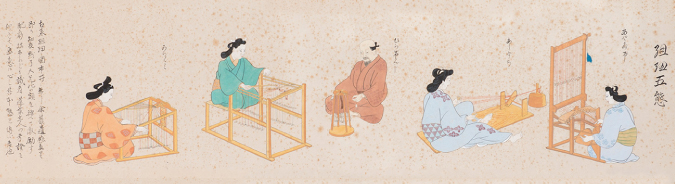

▲This is a Japanese painting of people making braided cords on a braid stand, which is carefully displayed in their workshop.

ーI see. After all, industry is only possible when there is a growing demand from the general public.

That’s right. At the same time there was increasing demand for craftmen who can deal braid making by machine. My grandfather, Ikkei, and my father were both craftsmen who specialized in machine assembly, while my mother, Fumiyo, specialized in hand braiding.

This is why we do both machine assembly and hand braiding. Most braiding shops do one or the other, but I think this form is rare.

ーToday, we are excited to have oppotunity to see both machine assembly and hand braiding.

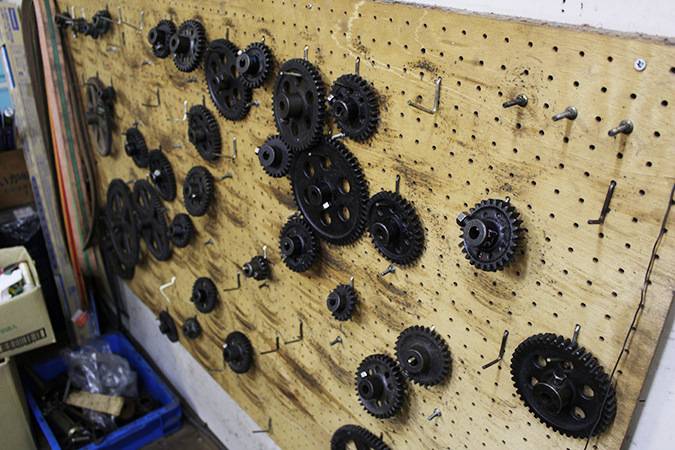

Either mechanical or hand-assembled, braid maiking cannot be operated without knowledge and skill, so both are very important. As you will see later, the machines are old…some of the parts are not easy to get if broken. I manage to get machine parts from fellow makers when they disassemble the old machine.

Work equipment is very important for us, whether it is machine or hand braiding.

ーThank you. We feel lucky to see your workshop!

Can you tell us how did you two as 4th generation decide to engage to your family bussiness?

Didn’t you find it difficult to carry on the traditional craft since you had seen the hard work of your family as you grew up?

▲Kenta, Older brother

”I’ve known since I was a little boy that I was going to do this job, so I didn’t think it would be particularly hard. ”

▲Yasutaka, Younger brother

“Regardless of what kind of work you choose, there are always hard aspects to it, and I don’t think it’s harder because it’s a traditional craft. Besides, the more I studied design at a college, the more I started to imagine what I could do with my family business… I chose this job because I wanted to try these my ideas, rather than because I wanted to take over or had to. “

ーIs there anything that is important to you in your work?

The quality of the kumihimo and tassels themselves are, of course, of the utmost importance, but to ensure that the value of the products and techniques does not drop, it is important to finish the final process, even the packaging, in a neat and beautiful manner.

ーIndeed, every time I open the box from you, I get impressed to see how scissors are beautifully lined up in the box. Thank you very much for that.

Thank you for saying that!

ーAnd lastly, Shunsaku-san, Please tell us about your thoughts on continuing the tradition and your vision for the future.

In the past, there were nearly 100 craftsmen, but now the number has dropped to nearly 20.

Kumihimo production is based on the division of labor, and the loss of “masters who teach us how to make kumihimo braid and craftsmen who work with us” is a crisis for the production area. There are craftsmen who make the yarn, and there are dyers who dye the yarn, so we are able to work with them. If there are no successors to the dyers, we have to do the process ourselves. It could be even more difficult in the time of the two of my sons than in my time.

I believe, however, that if the two of them cooperate and help each other, they will be able to manage.

In fact, Kenta is now learning how to dye from a craftsman, and if each of us can utilize what we have learned, we can make up for the lost skills.

Also, I believe that it is very important to pass on tradition. If there is no inheritance of skills and traditions, there will be no innovation.

ーFrom the words of your son and your thoughts about the work, I felt a sense of hope for the future.

Thank you!

After the interview, we were invited to see the dyeing process.

With five of Cohana’s original traditional Japanese colors as samples, the pure silk threads are dyed skillfully and vividly.

▲Kenta is in charge of dyeing the yarn. He dries the yarn in the shade for half a day to make sure the color matches the sample.

▲The dried yarns are gathered into several strands using a tool called “Zagari”.

Next, we went to the machine assembly workshop.

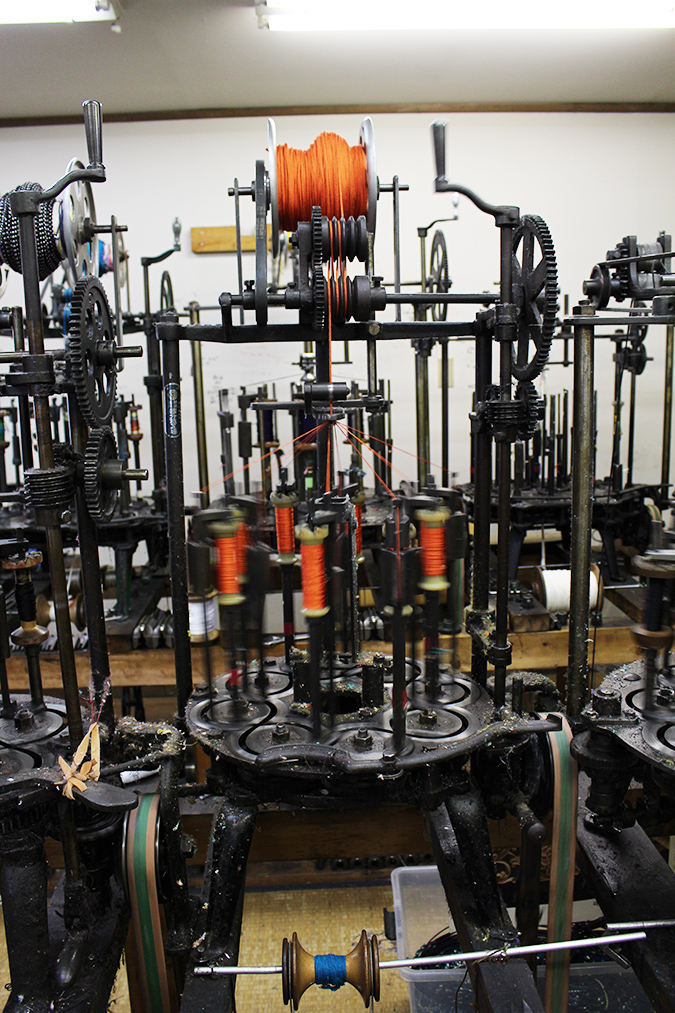

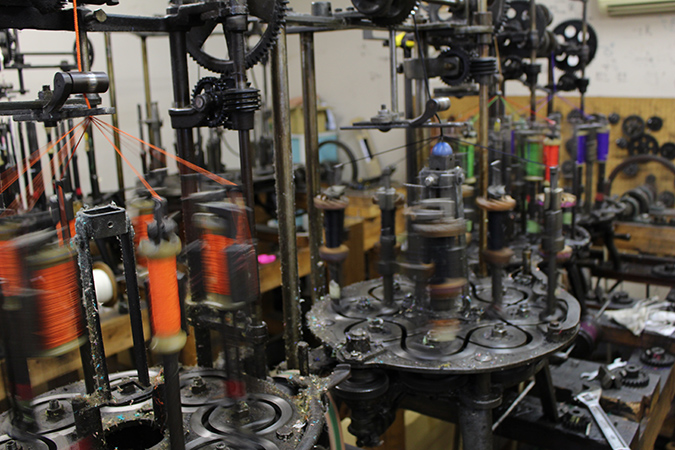

As we entered the workshop, we were surrounded by the sound of clacking and bustling and encountered beautifully made machines.

▲ Eight spools of yarn rotates at high speed, and the braids are assembled.

▲Many of the tasteful wheels of various sizes have been acquired from old machines.

”I’m currently working on a fine kumihimo, but I can make it a little thicker depending on the adjustments I make.”

”It is important to lightly twist the yarn before putting it through the machine. Here is the twisting machine.”

▲Twisting machine. If you twist it in the wrong direction, it can be a big trouble.

As I had heard in the interview, the machines were old, but I could tell from the appearance of the workshop that they were carefully maintained and used with care.

While inheriting the history, traditions and techniques of the region, they create something new.

The sight of silk threads and iron interwoven with the intentions of these artisans was firmly imprinted on my eyes.

At the end of the day, we went to a hand-assembling workshop.

▲There are various types of braided platforms, such as high platforms, twirled bamboo platforms, and round platforms.

Various patterns are created by moving the “Kumidama,” a weight used to make the yarn taut, in turn. In the quiet studio, the sound of the Kumidama clashing gently echoed. The two craftsmen’s hands move smoothly, and they seem to have the procedure already in mind.

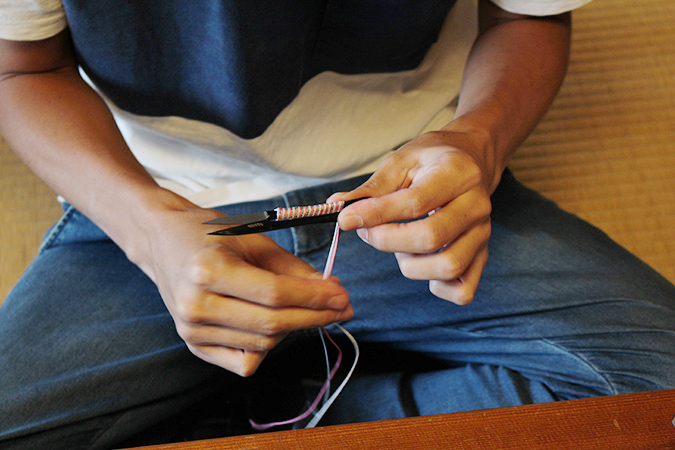

We were also able to see how Cohana’s thread cutting scissors are made with their braid.

▲ Take three strands of thread and wrap them around the handle of the snips.

▲Thread the button through and tie tightly.

The delicate handiwork and ingenuity of the artisans was utilized in the small thread snips that fit in the palm of my hand.

We left the workshop hoping that through Cohana’s products and interviews, we could convey to our customers even a little bit of the spirit of Japanese craftsmanship.

▲On the way home, the countryside around the workshop was bathed in beautiful sunset light.

Matsushima Kumihimo

At our workshop in Iga, the birthplace of kumihimo, the craftsmen use mainly high, round, and square stands, as well as other types of braid suitable for different purposes and patterns, to produce strings with a unique braid flavor. The luster of the silk yarn is brought out, and we continue to pursue the beauty of tradition.

Matsushima Kumihimo HP http://www.iga-kumihimo.com/